CHAPTER 6

Sabre® MK- 46 Crowd Management canister is the most effective OC aerosol projector for large scale management of unruly crowds. At 46 oz, the MK-46 holds approximately three times the fluid product than the MK-9. This allows for massive subject and area contamination prior to the need for refill.

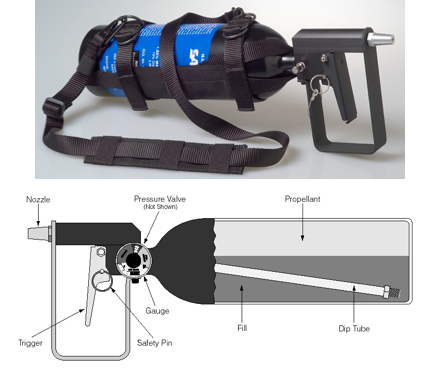

6.1 MK-46 CROWD MANAGEMENT SYSTEM

The largest of all Sabre® canister systems, the MK-46 Crowd Management is an essential tool for any crowd management team. It can deliver an incredible volume of OC up to 30 feet (10 meters). For this reason, operators should not deploy the MK-46 at an individual that is closer than 12 feet (4 meters).

The design and size of the MK-46 limits the flexibility in delivery. This creates an optimal delivery platform that is low and hard to elevate. For this reason, during crowd management deployment it can be very advantageous for the operator to find an elevated delivery platform on which to stand. This will allow for the stream to be delivered past the front line of the crowd. Delivery behind the front line will break up the crowd and prevent trampling or squeezing when the product is delivered to the front line.

6.2 NOMENCLATURE OF THE MK-46

6.3 SABRE® MK-46 SECURITY FEATURES

Safety Pin

The removable safety pin. Similar to a grenade pin, the safety pin inserts into an opening under the trigger preventing accidental depression. The pin MUST BE REMOVED in order for the MK-46 to fire. The safety pin can be re-inserted at anytime to assist in preventing accidental discharge of the MK-46. The safety pin has an wire lanyard that assists retaining the pin for future use. The safety pin should be securely in place any time the MK-46 is being transported.

6.3 SABRE® MK-46 SECURITY FEATURES

Trigger Guard

The MK-46 has a large metal brace surrounding the trigger mechanism. This bracing provides adequate room for the operator to insert their hand but is solid enough to assist in protecting the trigger from accidental discharge.

Pressure Gauge

The MK-46 has a pressure gauge attached to the trigger assembly. The gauge assists the operator in knowing when the canister’s volume is low or almost empty. It also assists in knowing if the canister is under pressure prior to refilling. Periodically check to ensure the gauge is still in the green zone.

6.4 MK-46 RETENTION GRIP AND DELIVERY

The MK-46 utilizes a shoulder strap harness to assist in deployment and security. The strap is designed to be worn over the shoulder to allow the operator to operate the MK-46 with a single hand. This delivery platform keeps the canister protected by tucking the MK-46 under the operators arm. It does create a low firing platform which assists in front line delivery under shields and low delivery to crowds defending by hiding their faces.

Prior to deployment, check the gauge and ensure there is adequate pressure and volume. Ensure the safety pin has been removed. Operators should ensure that they avoid discharging into the wind to prevent cross contamination. Again, avoid discharging at ranges closer than 12 feet (4 meter) as soft body tissue damage may occur.

6.5 MK-46 FILL AND REFILL INSTRUCTIONS

A Charged MK-46 is under high pressure. Never unscrew a charged unit. Always ensure all pressure has been released prior to refilling the unit.

Always wear proper eye protection and rubber gloves when refilling.

6.5 MK-46 FILL AND REFILL INSTRUCTIONS

6.5 MK-46 FILL AND REFILL INSTRUCTIONS

MK-46 Fill / Refill Instructions

- Invert canister and depress valve lever to release all remaining pressure.

- Make sure the dispenser has no pressure remaining. Then, unscrew the valve head from the bottle and carefully empty any remaining formulation. Dispose of remaining formulation according to local regulations.

-

Place funnel into neck of bottle and carefully pour the pre- measured contents into canister.

(NOTE: Do not put live formulation in a unit marked for Inert.) -

Replace O-ring on the valve and place valve back onto canister and hand tighten.

(NOTE: If filling new hardware for the first time, the valve will already be equipped with an O-Ring.) - Remove the protective cap from the Schrader Valve.

6.5 MK-46 FILL AND REFILL INSTRUCTIONS

- Before beginning pressurization, verify that the inflation chuck does not lock down on the stem.

- Turn on the nitrogen gas cylinder and adjust the regulator to approximately 250 PSI.

- Prepare the canister for pressurization by inverting the canister.

- Engage the air chuck and begin pressurizing. Disengage the air chuck when the needle on the gauge is in the green.

WARNING: NEVER EXCEED 300PSI. WHILE PRESSURIZING, IF YOU HEAR A HISSING NOISE, STOP PRESSURIZATION. WHILE PRESSURIZING, IF THE GAUGE NEEDLE DOES NOT MOVE, STOP PRESSURIZATION.

6.5 MK-46 FILL AND REFILL INSTRUCTIONS

- If the canister is accidentally over pressurized, depress the valve lever while holding the canister in an inverted position to relieve the excess pressure.

- Replace the protective cap on the Schrader Valve.

- Mark refill date and expiry date of the OC formulation on the side of the canister.

6.6 MK-46 TRANSPORT AND STORAGE

Operators should ensure that the safety pin is securely in place behind the trigger prior to transporting the MK-46 in any vehicle. If used and not completely emptied the unit can be stored at room temperature and may be utilized again prior to the expiration date of the OC formulation.